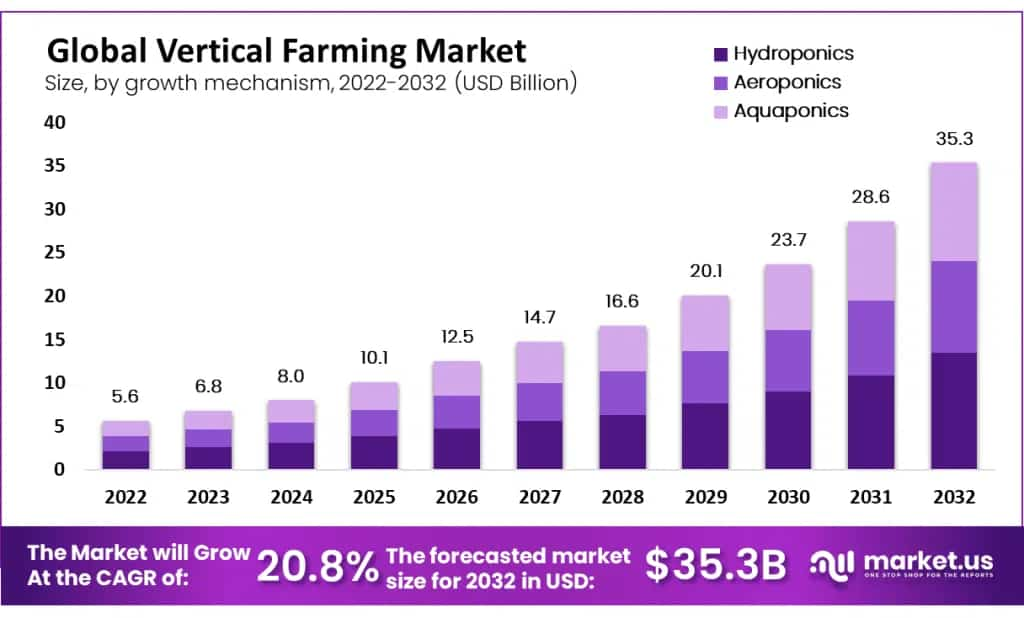

Vertical farming is the process of growing plants on layers that are stacked vertically. Inside, crops are growing in lights and temperatures that are not natural. Its goal is to get a lot done in a small area. It uses hydroponics, aquaponics, and aeroponics techniques that don’t need dirt. Less water and chemicals are needed for vertical farming. Since the foods are grown indoors, they don’t have to worry about the seasons, so they produce a lot all year. This method can be used to grow lettuce, peppers, and other green plants. Japan was one of the first places to use vertical farming. We will dive deep into their technology in this session.

What is vertical farming? Which of the following best describes it

Vertical farming is an innovative hydroponic farming application that has gained significant traction over recent years. While traditional methods rely on only horizontal production planes, vertical farming takes an innovative approach by employing both horizontal and vertical planes of production for maximum production per cubic unit of land use instead of square units, making it a highly efficient and sustainable method of agriculture. Vertical farming encompasses various techniques with each technique having its specific technologies and use cases most common vertical systems include stacked horizontal systems and vertical surface systems. Such as,

- Stacked Horizontal Systems- Multiple layers or tiers of growing platforms characterize stacked horizontal systems.

- Vertical Surface Systems- Vertical surface systems can be divided into three subcategories: green walls, cylindrical growth units, and vertical tower units.

Although each vertical farming design offers its own set of benefits and drawbacks, combining two systems–isolated vertical system and green wall system–has proven particularly promising in urban indoor farming environments.

How Does Vertical Farming Work?

Due to our growing global population expected to exceed 10 billion by 2050, providing enough food in an efficient, sustainable, and cost-effective way becomes ever more significant. Traditional farming methods are increasingly under pressure from seasonal weather patterns, transportation challenges, and limited resources. Vertical planting looks like a good way to deal with these problems. Vertical farming entails growing crops in controlled, enclosed environments where conditions can be carefully managed to maximize yields. Facilities like AeroFarms in New Jersey use vertical racking systems to optimize space, enabling them to be located closer to urban areas for less transportation costs and reduced carbon emissions. Breaking how vertical farming works and if someone wants to build it then how can he build a vertical farm in easy methods,

- Choose a location – Consider available space, sunlight, electricity, water access and temperature control need when choosing your location. Warehouses, greenhouses, shipping containers, or indoor spaces could all make ideal spots.

- Select crops – Leafy greens, herbs, strawberries, and other crops that grow well vertically and have good market demand. Make sure to choose crops suited to your growing system.

- Set up growing structure – Install vertical shelves, towers, rails, or other structures to support vertical growth. Use durable, food-safe materials. Shelves should be adjustable as plants grow.

- Install hydroponic system -Build through your hydroponic system. This could be deep water culture, the nutrient film method, aeroponics, or something else. Don’t forget to include the tanks, pumps, tubes, and other parts that are needed.

- Add lighting – LED grow lights that provide full spectrum light work well. Make sure lighting is sufficient for selected crops.

- Monitor and control environment – Use heaters, AC, humidifiers, dehumidifiers, and fans to keep temperature, humidity, and airflow optimized.

- Establish irrigation system – Set up timers and pumps to automatically deliver nutrient solutions. Monitor and adjust EC, pH, and nutrient levels.

- Transplant seedlings – Transplant sprouted seedlings from the nursery area into a vertical system. Space appropriately based on the crop.

- Maintain and harvest – Prune, and train plants as needed. Check for pests and diseases. Harvest produce and restart cycle.

When was vertical farming invented?

Vertical farming was first pioneered in 1915 by American geologist Gilbert Ellis Bailey, who coined the phrase “vertical farming” to refer to using explosives for farming underground. Vertical farming as we know it today was first proposed in 1999 by Dickson Despommier, an environmental health science professor from Columbia University. Key events in its history,

- 1915: Gilbert Ellis Bailey coined the term ‘vertical farming’ to refer to underground agriculture using explosives, while in 1951 Armenia hosted its inaugural true vertical farm with tower hydroponic units.

- 1999: Dickson Despommier and his students at Columbia University introduce the modern concept of vertical farming in urban high-rises 2011: AeroFarms opens successfully in Newark, New Jersey under Cornell professor Ed Harwood’s supervision.

Although vertical farming has existed in various forms since ancient times, the modern vision of commercial vertical farming incorporating hydroponics, aeroponics, LED lighting, etc. into urban settings originated with Dickson Despommier’s work at Columbia University in 1999 – his efforts paving the way for further innovation throughout the 2000s and 2010s to give birth to large-scale vertical farms such as AeroFarms today.

What is the biggest problem with vertical farming?

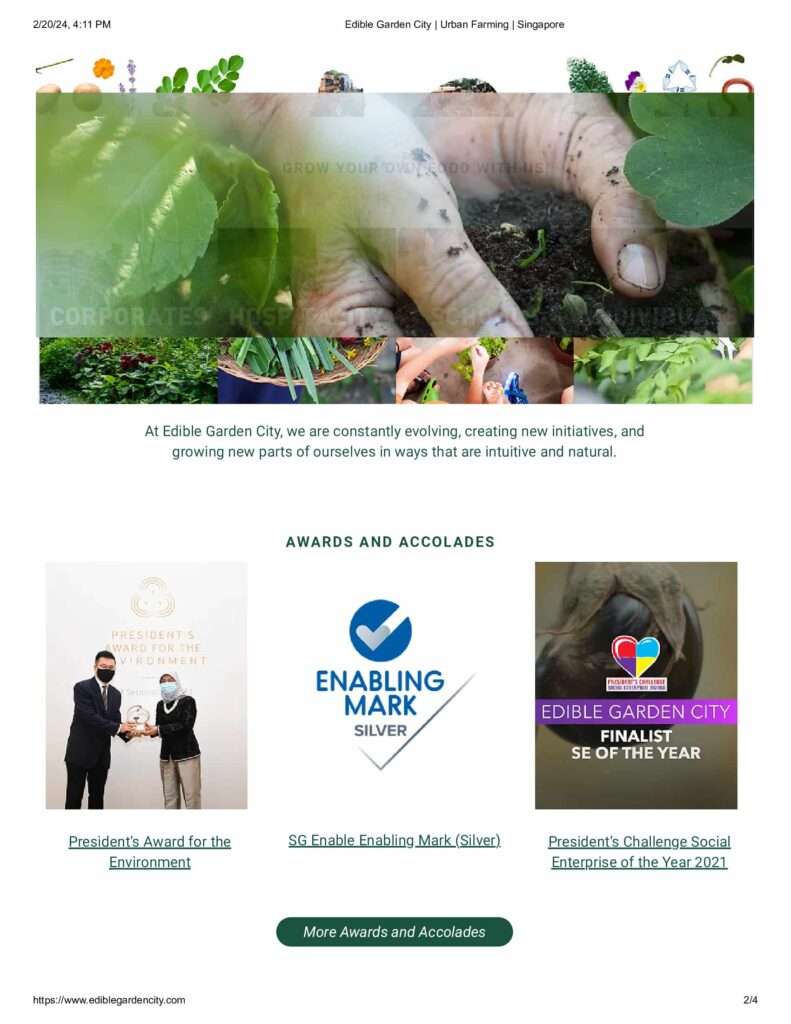

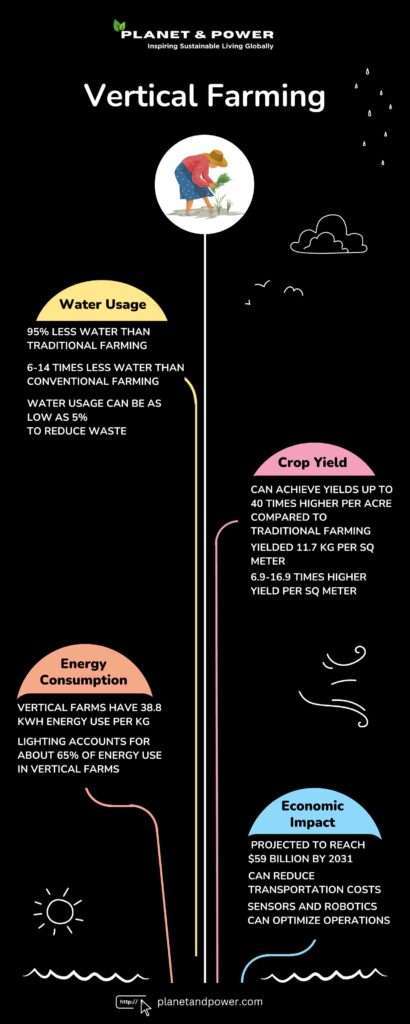

Indoor farming (also known as vertical farming) was originally considered the future of agriculture because it could produce year-round in controlled surroundings and cut food miles and land and water use, according to Financial Trade. Vertical farming has generated huge hype and billions in investment over the last five years, but it still faces problems. Layoffs and failures make its long-term viability uncertain. Pittsburgh-based Fifth Season, French enterprise Agricool, and Dutch Glowfarms are three famous vertical farming companies that went bankrupt. Former European vertical farming leader Infarm is leaving Europe. Some companies flourish and profit despite growing energy prices. As consumer energy prices rise, vertical farms must spend a large amount of their operating costs on electricity to operate LED lights, ventilation systems, and temperature controls. In 2021, some farms spent 40% of their budgets on energy, up from 25% in 2020. Some vertical farms use renewable energy to address this. Scaling this strategy is hard. To power an 11,000-kilogram lettuce vertical farm, 6,000 square meters of solar panels are needed. Vertical farming requires expensive equipment and manpower, costing two to three thousand dollars per square meter. This price does not include building or rent costs, but a Wageningen University study suggests investing in traditional fields might cost 50 cents to 50 euros per square meter. Geography is crucial to vertical farming’s profitability. Dubai, with its cheap energy costs and food security-focused government, is ideal for vertical farming. This year, one of the world’s biggest vertical farms began producing over 3000 kilos of green vegetables every day for Emirates and other airlines. Our analysis implies that only technological and automation advances can save vertical farming. Likewise,

Is vertical farming profitable?

Well in that case our job is to provide all the latest innovations, facts, and behind-the-scenes to our readers. It will be your take whether you want to grant this as beneficial or not. Let us know by Cold mail when you have any thoughts. Now let’s get into this,

Vertical farms are a revolutionary approach to growing food that involves cultivating crops indoors, without the need for traditional soil-based methods. By utilizing hydroponic or aeroponic units, these farms offer a range of benefits, such as reducing water and fertilizer usage, expanding the variety of crops that can be grown, and potentially increasing the nutritional value of the food. Concerns have been expressed over the long-term viability and scalability of vertical farms. Plants grown on these farms receive all their essential nutrients in hydroponic or aeroponic units that deliver nutrients directly to them any surplus nutrients and water can be reused again to minimize waste production. Unlike plants in traditional fields, vertical farm plants cannot rely on sunlight and rainfall, so controlling temperature and light in these indoor environments requires a significant amount of energy. Vertical farms have gained popularity due to their potential to provide fresh produce in urban areas and reduce the environmental impact of traditional farming methods. By operating in supermarkets, disused city buildings, or old bomb shelters, they can deliver fresh food to local restaurants and supermarkets. But there are still big problems that need to be solved. Those are,

- Energy Consumption

- Renewable Energy Potential

- Expanding Crop Variety

- Industrial Applications

Vertical farms have proven their value by providing fresh, locally sourced food to urban areas and reducing the environmental impact of traditional farming. However, there are still issues to resolve for vertical farms to remain effective and flourish in the future. With technology constantly improving and further research being conducted into their use as food production methods. It may become even more significant as time progresses. Vertical Farm Research highlighted its economic viability by producing significant fruits, vegetables, and fish while simultaneously reducing water and power usage and suggesting markets for vertical farms.

What are 3 pros and 3 cons of vertical farming

As our scientific research and experience shows,

Pros

- Increased Efficiency and Productivity: Vertical farming significantly enhances efficiency by taking advantage of vertical space to optimize yields compared to traditional farming methods, often leading to greater yields compared with their predecessors. It’s especially efficient at optimizing land usage in urban settings where space may be limited by stacking crops in vertical layers.

- Reduced Environmental Impact: By controlling the growing environment, vertical farming reduces pesticide and fertilizer use while simultaneously conserving water usage through recirculation and cutting transportation costs and emissions by placing food production closer to consumers.

- Vertical Farms Allow Year-Round Crop Production: Vertical farms can produce crops year-round regardless of seasonal changes, weather conditions, or geographic limitations, providing more stable food supplies as well as expanding crop varieties. This continuous production cycle may increase food supply stability while increasing crop diversity potential.

Cons

- Initial Investment and Operating Costs Are High: Setting up vertical farming requires significant upfront capital costs in terms of buildings, LED lighting systems, and climate control systems ongoing operational expenses associated with lighting and climate control can add further costs – potentially making produce more costly overall.

- Technological and Operational Challenges: Maintaining ideal conditions for plant growth requires advanced technology and constant oversight, with failures leading to significant losses if left unaddressed. There can also be steep learning curves associated with optimizing complex systems like vertical farming.

- Energy Consumption and Sustainability Concerns: Vertical farms may use artificial lighting and climate control systems that consume significant energy, which could counteract some of their environmental benefits if the energy used does not come from renewable resources.

We confess these 6 points are a mixture of our team’s experience and data across the web.

Vertical farming technology

Everyone is talking about old things and making copy-paste from others. Which is a little bit disappointing. We will discuss “The Robot Technology in Vertical Farming” Be with us. Plenty, a company based in Compton, California, is at the forefront of vertical farming. Their vertically grown food offers numerous benefits over conventional agriculture:

- Less dependency on environmental factors: By cultivating crops indoors, vertical farming reduces the reliance on weather conditions and ensures a more consistent supply of food.

- Reduced energy cost

- Year-round availability: Vertical farming systems enable the cultivation of crops in areas or during seasons when they would typically not be available, ensuring a steady supply of fresh produce.

- Optimized growth conditions

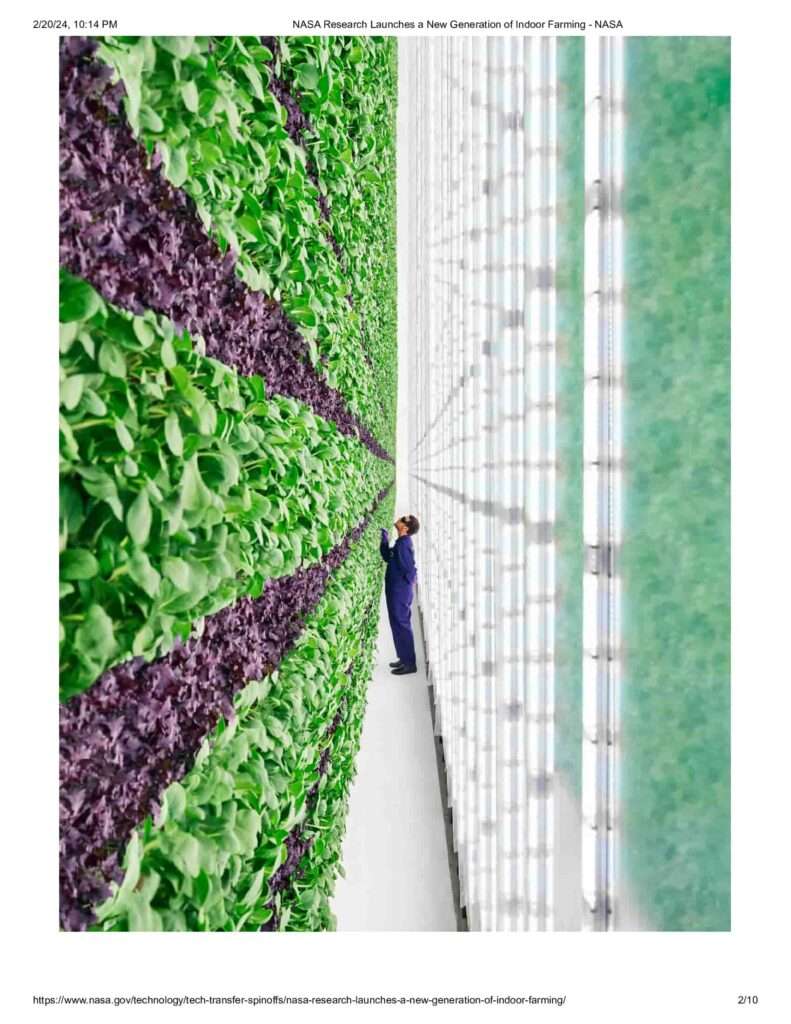

Plenty Farm’s vertical farming facility in Compton utilizes advanced technologies to maximize crop production. All aspects of plant growth – from seeding through harvesting – are carefully managed within this facility. Start by planting seeds in trays, where they receive water and nutrient mix to grow successfully. Plants then move to the propagation room where special conditions encourage germination. Once ready, plants are transplanted into vertical towers and transferred to grow rooms where they mature under Plenty’s proprietary lighting system – a crucial factor in plant development. Unique in design, its sideways-oriented lights and integrated ventilation systems ensure efficient photosynthesis while offering customized spectrums to promote optimal plant development. As harvest time nears, Plenty’s automated systems and conveyor belts efficiently transport the plants from one stage to the next. A large robotic arm loads towers into a harvester where blades slice off the greens. Quality control is essential in guaranteeing fresh and healthy produce reaches the market, and Plenty’s success in vertical farming has provided further opportunities and innovations. The company is exploring vertical farming to produce strawberries and tomatoes, with possible applications beyond these species. Vertical farms could become high-tech farms capable of creating ingredients and proteins not previously imagined by taking advantage of vertical farm environments scientists and farmers alike can push food production further and meet future challenges more effectively.

Vertical farming benefits

Various vegetables are being cultivated in a room without sunlight. One of Europe’s largest farms is growing various types of vegetables including lettuce leaves. Being different from the traditional process, this method takes up less space and uses purple LED light for photosynthesis. An entire vertical farm of 14 floors has been built from ground to roof. Nordic Harvest produces quality food all year round. In this way no harm is being done to nature and no carbon emissions are being produced. Energy from windmills is used here. Everything is being produced in-house. With this method, hazardous fertilizers don’t have to be put into the air. And no waste of any kind is thrown into the sea. This is the largest vertical farm located in the open of Denmark. In the 7000 square meter vertical farm in this hall, vegetables and lettuce leaves will be cultivated first. The entrepreneurs of this farm said that fruits and vegetables will be cultivated later. A joint venture between Nautic Harvest and Taiwan’s Yes Health, the firm has set a target of producing 1,000 plants over the next year. They say this farm can compete with farmers. The use of this technology will reduce the use of agricultural land. They aim to grow vegetables in this way and sell them in the city. In this method, it is possible to produce 15 times in a year on the same soil whereas these can produce at most twice using their so-called agricultural methods. A study from the World Bank in 2016 said that 37% of the world’s land is used for farming. Which is constantly threatening climate change and the availability of cultivable land. The problem program says one-third of arable land is losing its working capacity. Which is creating food production uncertainty.

We believe our examples will give enough encouragement to think about this farming method’s benefits.

Vertical farming equipment

We will simply name the pieces of equipment so that this blog won’t be boring for our readers. If you know how to use them never hesitate to reach us.

- Vertical Grow Racks – A flexible vertical grow rack system is what vertical farming is all about.

- Mobile Carriages – Your grow rack is like the bones of your grow room. The mobile carts are like the muscles that move the bones where they need to go.

- Grow Trays – After putting together the framework, or skeleton, it’s time to add the grow plates, which are like the organs.

- Lighting – Lights are very important for cannabis plants because they help them grow healthy and strong.

- Air Flow – Making sure there is enough airflow is important for keeping plants healthy and keeping pests and germs out of your building.

- HVACD -This is like the lungs of a straight growth system in a manner that is symbolic.

- Irrigation and Fertigation Systems.

- Grow Sensors and Monitors.

- Mobile Carts.

- Elevate Platform System – This is a strong but lightweight, movable deck that lets growers get to the top level of Pipp’s Multi-Tier mobile grow racks quickly, easily, and most importantly, safely.

Vertical farming projects/vertical farming companies

We are showing the world most top and successful vertical farming projects along with the most advanced ones for 2024. Well, The world’s most advanced vertical farm opened in Gloucestershire in 2023 named Jones Food Company.

Rest are,

- AgriCool

- Bowery Farming

- Freight Farms

- AeroFarms

- GP Solutions

- Crop One Holdings, Inc.

- One.

- Altius Farms, Inc.

- Sky Greens

- Plenty Unlimited

- Eden Green Technology

- Vertical Harvest

- Green Spirit Farms

Vertical Farming Singapore

Singapore may conjure images of a modern, futuristic city with towering buildings and lush vegetation – but one thing it lacks – farms. At the moment, 90% of Singapore’s food comes from outside the country. This makes the island exposed to problems in global supply lines. To combat this vulnerability and strengthen the resilience of their food supply, the Singaporean government has set an ambitious goal of producing 30% of their food by 2030. Singapore was traditionally dependent on agriculture for only 4% of GDP in the 1960s.

As Singapore expanded urbanly, its focus shifted away from farming towards manufacturing industries. At one point in time, agriculture played almost no role in Singapore’s economy. Bjorn Low, a former digital marketer who is now an urban farmer and co-founder of Edible Garden City, saw that Singapore needed to get people interested in growing their own food again. Since 2006, he has witnessed this sector evolve from being led by smaller farmers to becoming an attractive source of investment from both government and industry. Urban farms have spread throughout Singapore from homes and hotels to shopping malls and schools. Singapore, with limited land for traditional farming, has turned to innovative solutions to increase food production. One such method is indoor farming – where crops are grown under controlled environments using water instead of soil and pesticides – such as Artisan Greens and Sky Greens which use technology to optimize conditions for specific plants.

Singapore is not the first city to adopt urban farming as an answer to self-sufficiency needs Cuba pioneered urban farming infrastructure in the 90s due to a need for self-sufficiency Sao Paulo, Seoul, and Tokyo have also implemented urban farming initiatives however, Singapore stands out as a case study in developing an agriculture industry from scratch.

Indoor vertical farming

AppHarvest was created by Jonathan Webb with the belief that everyone deserves access to healthy fruits and vegetables. They aim to find ways to increase production with limited resources while respecting nature as the priority. With the global implications of high-tech indoor farms, it becomes possible to produce large quantities of food while having minimal impact on the environment. AppHarvest plans to establish one of the largest leafy green facilities in the US at Berea and establish a network of high-tech farms across Central Appalachia. AppHarvest is revolutionizing farming through innovative technology combined with an emphasis on sustainability. Technology continues to adapt as food production challenges change from ancient tools like the wheel to today’s AI, robotics, software, and sensors technology has evolved tremendously over time in meeting those challenges. The western US water crisis requires immediate attention. AppHarvest believes that innovative farming methods can help ensure more efficient water usage. By installing indoor farms like Berea’s, water consumption can be drastically decreased. AppHarvest’s closed system captures rainwater, which is then distributed evenly among plants using sensors. Indoor farms like that shown by AppHarvest boast unique features and benefits their advanced technologies require 90% less water than traditional farms. AppHarvest believes in creating an ecosystem for future farmers who use technology to address food production challenges sustainably, using their closed system to minimize contamination risks and ensure food safety. Indoor farms can operate 24/7 thanks to LED lighting which enhances plant growth at nighttime. Their goal is to inspire young people to consider careers in farming through AppHarvest’s goal of inspiring young people towards agriculture as an option they aim to establish pathways leading to sustainable food production that provide pathways for young people looking into farming careers.

Hydroponics vertical farming

Welcome to the world of hydroponic fodder farming using containerized hydroponic techniques and equipment. By employing proven techniques and tools, you can ensure an uninterrupted supply of high-quality feed for farm or zoo animals. Step one should include soaking 130 pounds of barley seeds overnight. An overnight soak not only cleanses seeds to reduce contaminants, but it also breaks their dormancy and triggers sprouting. After being soaked for 24 hours, these seeds are transferred into a push cart connected to a hose for convenient transport to grow trays. A containerized hydroponic fodder farm features seven trays in each tower and six towers altogether, creating optimal growing conditions in this controlled climate environment housed within a shipping container. Utilizing this setup, you can harvest approximately 850 pounds of nutritious barley grass each day. Once seeds are in grow trays, uniform distribution for optimal growth should be ensured – which involves spreading seeds out evenly across all of them. In this way, every seed has an equal chance to grow and add to the overall crop. After two days, sprouts begin emerging by day seven they are ready for harvest as fully-grown fodder mats have formed around each one of them. Roots bind together naturally, making harvesting an entire mat an effortless process. And what’s even more incredible? Barley fodder provides vital nutrition for animals. Packed with protein, this diet offers a well-rounded nutritional program designed to increase hydration and overall health benefits for animals. By including it in their daily food routines, you gain greater control of their nutrition resulting in happier and healthier animals.

Types of Vertical Farming

Vertical farming is an innovative technique for growing more food in less space by using fewer resources. Utilizing layers or towers of vertical farms, farmers can increase growing space while scaling operations efficiently. We will look at hydroponics, aquaponics, and aeroponics, which are the three main types of vertical farming systems.

- Hydroponics – Hydroponics is the go-to commercial system for large vertical farms, unlike traditional farming which relies on soil. Instead, hydroponic systems cultivate plants without soil by submerging their plant roots in a nutritional liquid solution such as gravel and sand which enables their roots to take in macronutrients in large amounts.

- Aquaponics – Aquaponics goes one step beyond hydroponics by incorporating both plants and fish in one ecosystem. Fish are raised in indoor ponds, producing nutrient-rich waste that feeds directly to plants as a food source in return, plants filter and purify wastewater which is recycled back into the fish pond – creating an ecologically sound cycle of purification and reuse.

- Aeroponics – Aeroponics was initially developed by NASA to find more efficient ways of growing crops under adverse circumstances. The method involves growing plants without soil or significant water consumption – either air or mist environments are sufficient – without using soil as nutrients are sprayed directly onto their roots in aeroponic systems. While not as popular as hydroponics, aeroponics has gained momentum among small vertical farms that use soilless mediums such as rock wool in vertical tubular structures for maximum space efficiency.

Vertical Farming UK

In the UK, the berry business is flourishing with an estimated market worth over one billion pounds. Of the many types of berries sold therein, strawberries reign supreme with sales reaching 500 million pounds per year, unfortunately, though this requires imports for approximately six months of every year to meet year-round demand. Flex Farming is an innovative solution designed to revolutionize strawberry cultivation across Britain.

As strawberry demand increases, finding suitable sites for cultivation becomes increasingly challenging due to various regulations and water consumption restrictions. Flex Farming, an indoor vertical farm based out of Somerset, set out to address these difficulties head-on by placing sustainability at the core of its mission setting ambitious goals such as using 90% less land, decreasing water consumption by 95% and solely using renewable sources of energy – remarkable accomplishments which they have accomplished all.

The Most Advanced and Untouched Topics In Vertical Farming

Now in this section, we are going to touch on the latest facts and topics about vertical farming which are not covered by anyone in a single page. We don’t know why. But we are gonna break the first 2.

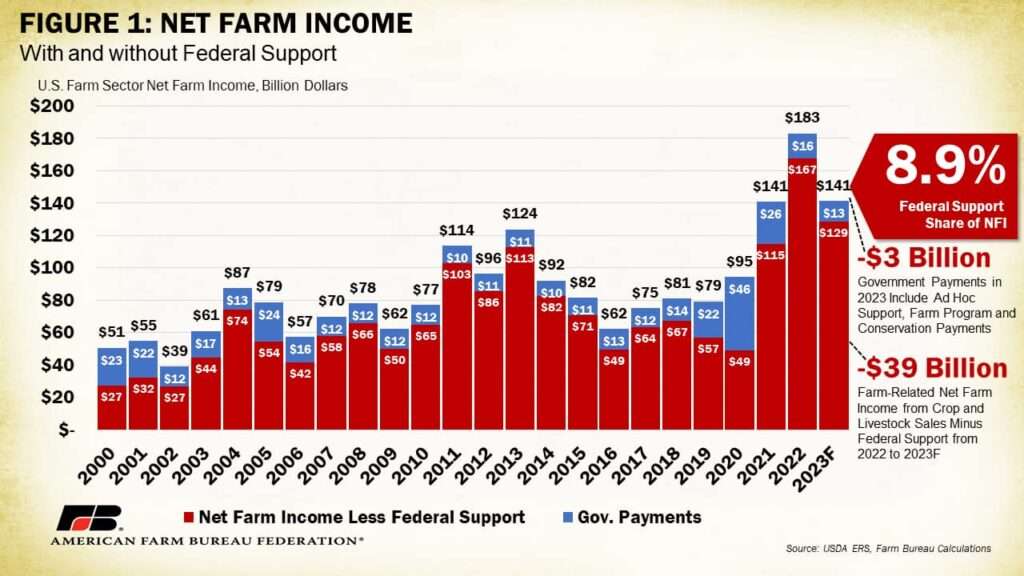

Innovative Funding Opportunities for Vertical Farms The U.S. Department of Agriculture (USDA) has made considerable investments in urban agriculture and innovative production methods, including vertical farming. Over recent years, significant funds have been set aside by the USDA to support such initiatives for instance, in 2023 alone it invested $7.4 million across 25 projects (just over 8 percent) out of over 300 applications received these grants are part of their larger effort of over $50 million pledged since 2020 in support of urban agriculture initiatives (U.S. DEPARTMENT OF AGRICULTURE). The USDA’s Office of Urban Agriculture and Innovative Production (OUAIP) gives funds to projects that make it easier for people in the area to get food, build up infrastructure for farmers, or help urban farms and food parks produce more (U.S. DEPARTMENT OF AGRICULTURE). Numeric data suggests that USDA interest rates were set in November 2023 for Operating and Ownership loans, while FSA offers guaranteed loans through commercial lenders at rates set by those lenders (U.S. DEPARTMENT OF AGRICULTURE).

Hydroponic Research and Development

Automation and machine learning technologies are increasingly being added to hydroponic systems for greater precision in controlling their growing environment. Real-time monitoring and adjustments of factors like nutrient concentration, pH levels, temperature, and humidity enable real-time adjustments of factors that influence plant growth conditions for increased yields and improved conditions for yield optimization (GreenHouse Grower).

IoT technology has revolutionized hydroponics by providing remote monitoring and control of systems. Sensors collect information on environmental parameters and nutrient levels that can then be analyzed to increase farm efficiency (Climate Control Systems). LED lighting technology has become an integral component of indoor hydroponic systems. Modern LED grow lights more accurately recreate sunlight’s spectrum spectrum for optimal plant health and yield. Precise management of hydroponic nutrient solutions is vital to optimizing plant growth. Studies have also explored recycled hydroponics, which may enhance water and nutrient use efficiency while simultaneously minimizing environmental impact. Water purification systems ensure the quality of water used in hydroponics farms, essential to plant health. Pest detection technology has also been developed to effectively manage pests in these facilities.

We are at the Ending

We tried to give the most possible options to think about the Vertical Farming. We have no idea did we succeeded or not. If you think our research and sharing of our own experience is worthy for you, then never hesitate to reach us out in no time.